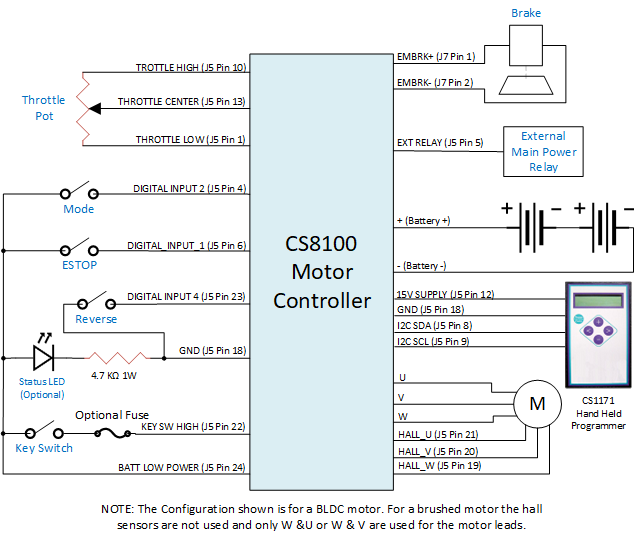

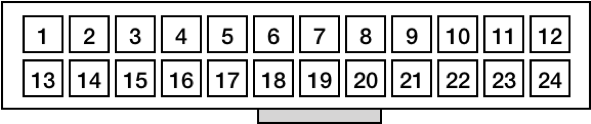

P250 Pinout

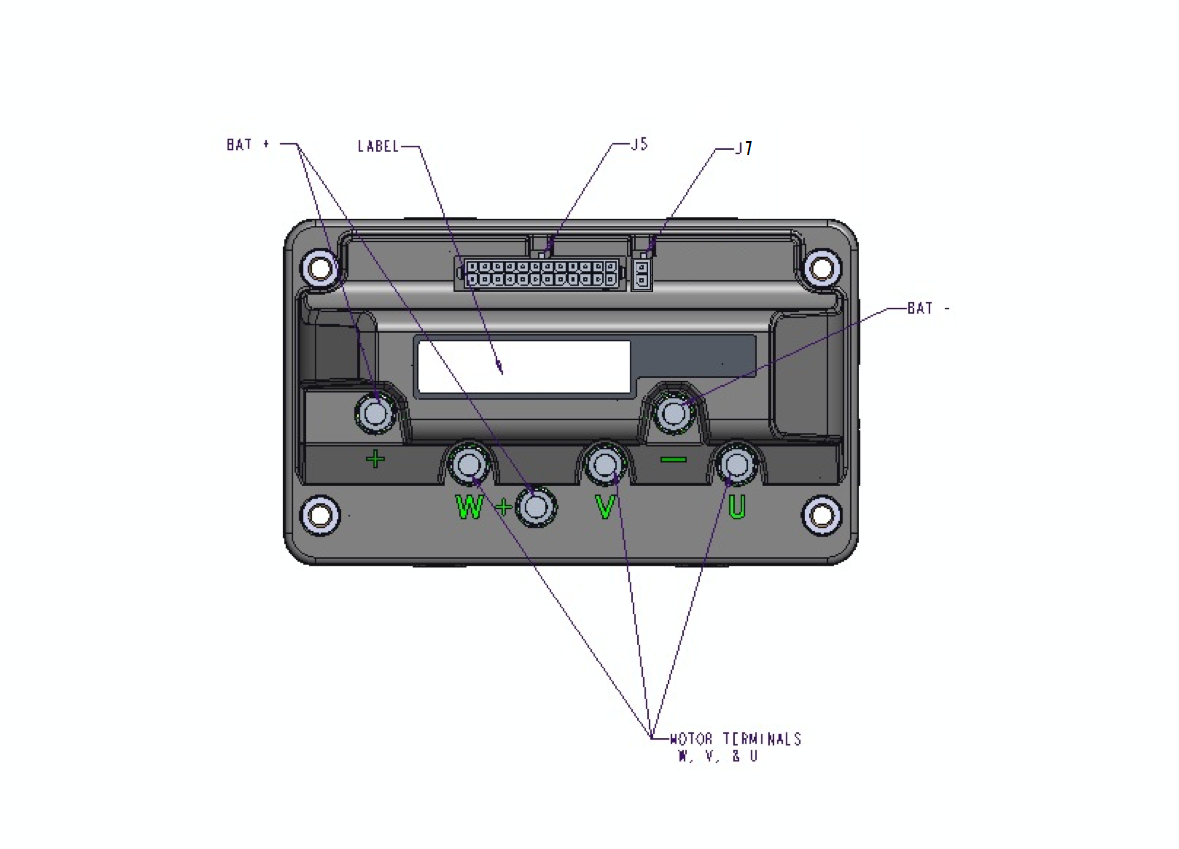

Connectors and Mates

| Label | Type | Function | Part Number | Mate |

|---|---|---|---|---|

| J7 | Two-pin | EM brake | ||

| J5 | 24-pin TE | Control and Status I/O | TE Connectivity 5-794630-4 Micro MATE-N-LOK | TE Connectivity P/N 2-794617-4 |

| + (Battery +) |

STUD M6 X 1 8MM | Positive voltage input | ||

| – (Battery -) |

STUD M6 X 1 8MM | Negative voltage input | ||

| W (Motor W) |

STUD M6 X 1 8MM | High current connection to motor | ||

| V (Motor V) |

STUD M6 X 1 8MM | High current connection to motor | ||

| U (Motor U) |

STUD M6 X 1 8MM | High current connection to motor |

J7 Brake

| Pin | Name | Description | Typical Use |

|---|---|---|---|

| 1 | EMBRK+ | VIN | EM Brake High Voltage |

| 2 | EMBRK- | < .4V , 1.25 A Max | EM Brake Ground |

J5 Control and Status I/O

| Pin | Name | Description | Typical Use |

|---|---|---|---|

| 1 | THROTTLE LOW | Throttle Pot Low (~0V): Low potentiometer reference for an analog throttle. | Throttle potentiometer |

| 2 | CAN-H | CAN Bus High (5 volt differential) | Status/Configuration |

| 3 | CAN-L | CAN Bus Low (5 volt differential) | Status/Configuration |

| 4 | DIGITAL INPUT 2 (GP_DIN2) |

Digital Configurable Input 2 | Seat Switch |

| 5 | EXT RELAY (P250 Only) |

Open drain output | Used to drive external protection relay |

| 6 | DIGITAL INPUT 1 (GP_DIN1) |

Digital Configurable Input 1 | Fault Input (Quickstop) |

| 7 | DIGITAL OUTPUT 1 |

Open Collector Output. Active > 2 V, Inactive = open circuit | |

| 8 | I2C SDA | I2C Data | Status/Configuration |

| 9 | I2C SCL | I2C Clock | Status/Configuration |

| 10 | THROTTLE POT HIGH | Throttle Pot High (~5V): High potentiometer reference for an analog throttle. | Throttle potentiometer |

| 11 | 5V SUPPLY | Regulated 5V Supply | Motor Hall Sensor Power |

| 12 | 15V SUPPLY | Regulated 15V Supply | Motor Hall Sensor Power |

| 13 | THROTTLE POT CENTER | Throttle Pot Center (0-5VDC) | Throttle potentiometer |

| 14 | KEY SWITCH LOW | Active < .8V, Inactive = open circuit | Keyswitch, see also KEYSW_HIGH |

| 15 | ANALOG IN | Analog Configurable Input | Temperature Sensor or Max speed pot |

| 16 | DIGITAL OUTPUT 3 |

Digital output. Requires mezzanine board customization to use this signal | Typically used as "Raise Charge" signal |

| 17 | DIGITAL OUTPUT 4 |

Digital output. Requires mezzanine board customization to use this signal | Typically used as "Brake Release" |

| 18 | GND | < 0.2 v with respect to GND | System Logic Ground |

| 19 | HALL W | Sensor position | Motor Hall Sensor W |

| 20 | HALL V | Sensor position | Motor Hall Sensor V |

| 21 | HALL U | Sensor position | Motor Hall Sensor U |

| 22 | KEY SWITCH HIGH | Active > 2 V, Inactive = open circuit | Keyswitch, see also KEY SWITCH LOW |

| 23 | DIGITAL INPUT 4 (REVERSE) |

Digital Configurable Input 4 | Forward/Reverse Control |

| 24 | BATT LOW POWER | ~VIN+, <1A. Current Protected Battery (+) Output | Used for KEY SWITCH HIGH |

Battery Connections

Use a properly-sized ring terminal to connect the battery leads.

Danger

Electrical charge may still be present on the battery connections even after the battery has been disconnected or power switched off. This stored charge will dissipate in a few minutes, but take care not to short the + terminal to a ground point because an electrical arc and possible damage to the controller may result.

Warning

Do not overtighten the terminal connections. Use a maximum torque of 20 inch-pounds. Overtightening may cause damage to the controller.

Motor Terminals

The P250 motor connections are made using the supplied M6, Torx T30 screws. A ring terminal such as TE Connectivity part number 321598 can be used to terminate the leads. Connections should be torqued to 40-45 inch-lbs.

Note

For a Brushed motor with only two motor connections, use the 'W' and 'U' connections

Warning

Do not overtighten the terminal connections. Torque to 20 inch-pounds. Overtightening may cause damage to the controller.

P250 Typical Connections