Throttle Configuration

The throttle is a proportional input signal, typically between zero and +5VDC; however for CAN Bus-capable controllers, it is also possible to provide the proportional input digitally.

The throttle input is conditioned, scaled, and limited according to the controller's settings. The output of throttle processing is a scaled digital value that represents the desired target drive level.

This target drive level is interpreted according to the Throttle Mode. For example, the throttle may target speed (RPM) or torque (PWM).

Properly setting up the throttle on a vehicle will ensure that you obtain peak performance and control of speed on the vehicle. The steps involved in setting up the throttle are:

- Setting basic throttle configuration

- Adjusting the throttle deadband

- Adjusting the throttle scale

- Adjusting the throttle failband

Note

If there is a potentiometer that sets the maximum speed on the vehicle, make sure it is adjusted to the maximum speed setting before configuring the throttle.

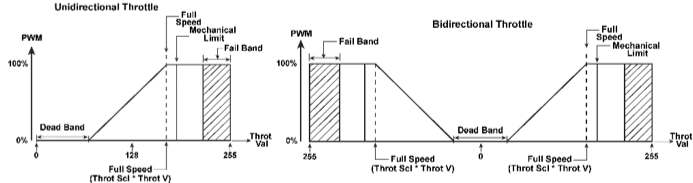

You should perform these procedures in the order they appear in this manual. When done properly, the vehicle will perform smoothly throughout the entire throttle range and provide the highest resolution of throttle control. The figure below shows the Throttle Deadband, Throttle Scale, and Throttle Failband for Unidirectional and Bidirectional Throttles.

Basic Throttle Configuration

THROTTLE POT CENTER Input

The Throttle Pot (THROTTLE POT CENTER) is a 0-5V input, measured on the THROTTLE POT CENTER pin. Various configuration parameters allow the behavior of the throttle to be customized. Other interfaces, such as ANALOG IN or Digital Throttle, can be used to limit or scale the THROTTLE POT CENTER throttle.

The THROTTLE POT CENTER interface is enabled by configuration register 0x0357.

ANALOG IN Input

The Analog-In (ANALOG IN) input is a 0-5V input, which can be configured for a number of functions. For example, it can be used as a Max Speed pot to modify the THROTTLE POT CENTER input.

Digital Throttle Input

The digital throttle accepts a proportional throttle value. It does not apply deadband, failband, or throttle scaling processing, since the system providing the digital command will determine under what conditions the motor should run.

In order to use digital throttle, the digital control feature and the digital throttle bits must be enabled in configuration register 0x0357.

Additionally, the Digital Control Options allow customization of the digital throttle behavior.

If enabled, the digital throttle input may also be used as a Max Speed Pot (Mixed Throttle) in combination with THROTTLE POT CENTER, by enabling the appropriate bit in configuration register 0x031F.

Uni-or-Bidirectional Throttle

A unidirectional throttle ranges from 0 to 100% with one direction of mechanical deflection. Its deadband region is at one end of the electrical range, and the failband is at the other.

A bi-directional throttle normally rests in the middle of the mechanical deflection range and scales from 0 to 100% in either direction. Its deadband region is in the middle of the electrical range, and the failbands are at the extremes.

Use the Programmer to set the Uni- or Bidirectional throttle, and to set the neutral position of the throttle. See Motor Configuration Register for information on registers 0x0317 and 0x0323.

Inverted Throttle

Enable this setting to invert the polarity of the throttle input (for instance, a unidirectional throttle will have its deadband region near the 5V end of the electrical range, and failband near 0V). See Motor Configuration Register for information on register 0x031F.

Throttle Offset

To ensure maximum range and resolution of the throttle, the throttle should mechanically rest at the neutral position (0V for unidirectional, and 2.5V for bi-directional). Mechanical variation of the resting throttle position can be compensated by adjusting the throttle deadband (see below). If there is a bias (offset) in the throttle's resting position, the throttle offset can be used to compensate for it.

- Locate the throttle at its resting position.

- Observe the throttle voltage reported by the Programmer.

- Adjust the Throttle Offset parameter until the Programmer reads the desired throttle voltage (e.g. 2.5V).

See Motor Configuration Register for information on register 0x035F.

Ramp Shape

The throttle ramp shape parameter sets the shape of throttle curves, determining the ratio of linear to logarithmic shape on the throttle curve. This value helps create a smoother acceleration profile or a more aggressive throttle response based on the application needs. A higher ramp shape value results in a more progressive throttle response when changing throttle inputs. Setting this value too high can roll off low-end throttle response too far and is generally not recommended.

Adjusting Throttle Deadband

The first step in setting up the throttle is adjusting the Throttle Deadband. Throttle Deadband sets the range of the neutral zone in the throttle input.

- Move the vehicle’s throttle to the position where you want the vehicle to start moving. It is recommended that the throttle position not be too far from the neutral position.

- While holding the throttle in the position where you want it to engage, adjust the value of Deadband up until you hear the relays click on the controller.

- Release the throttle mechanism.

- Throttle Deadband setup is complete.

See Configuration Register for information on register 0x0319.

Adjusting Throttle Scale

The throttle scale is a linear gain value that determines the throttle potentiometer voltage required for full speed. Under-adjusting the throttle scale will result in failure to reach full speed. Over-adjusting the throttle scale will result in reaching full speed too soon, and a reduction of speed control. To adjust the throttle scale, use the following procedure:

- Adjust the throttle scale value to its lowest setting

- Fully depress the throttle mechanism.

- Monitor the Scaled Throttle status and adjust the throttle scale setting until the Scaled Throttle status reads the maximum value.

- When complete, the Scaled Throttle status should read zero when the throttle is in its neutral position, and full value when the throttle is in its fully active position.

- If a bi-directional throttle is used, check the Scaled Throttle value for the other direction as well.

See Motor Configuration Register for information on register 0x031D.

Note

To compensate for mechanical tolerance and ensure that Scaled Throttle always reaches 100%, throttle scale should be padded by a value of 1 or 2. This will cause the Throt val to reach 100%, just shy of the nominal mechanical limit. In addition to compensating for mechanical tolerance, padding the throttle scale helps ensure constant full speed when the user has to hold the throttle at the maximum position for extended periods. Without the padding, the user may experience speed fluctuations as their grip on the throttle relaxes slightly over time.

Experiment with the padded throttle scale value to achieve desired results.

Adjusting Throttle Failband

The Throttle Failband is an area beyond the full speed throttle voltage that disables the motor. Throttle Failband provides a safety feature to protect against throttle shorts or open circuits, which could lead to undesired movement of the vehicle.

Note

Perform this procedure only after properly adjusting the Throttle Deadband and Throttle Scale

- Change the failband setting to its highest value (which disables the failband).

- Actuate the throttle mechanism on the vehicle to the full mechanical limit.

- Decrease the failband setting until the motor stops.

- Increase the failband setting by a small amount (e.g., 5-10 units) to allow additional tolerance.

- Because the failband fault has been activated during the adjustment process, you will need to cycle the keyswitch before the motor will run.

See Motor Configuration Register for information on register 0x031B.

High/Low Failband

If the Failband is configured to be less than the deadband value for a unidirectional throttle, the controller interprets this special case and applies the failband to both the upper throttle limit as well as the lower throttle limit. The resulting ranges are:

- [0 .. Failband]: Throttle fail (low)

- [Failband ... Deadband] Throttle deadband

- [Deadband ... (255-Failband)]: Throttle active

- [above (255-Failband)]: Throttle Fail (high)

After the failband value is determined for the upper throttle limit, the correct value for High/Low Failband is (255-failband).